horizontal drilling and how does it work?

The horizontal drilling or the directional drilling is very straightforward. This innovation came to execution around in the 1920s and is progressing till date. In prior occasions just single directional penetrating was conceivable. In the complexity, flat boring permits the excavators in the oil and gas industry to penetrate at an extensive variety of blessed messengers. This empowers the mineworkers to burrow a well a large number of foot down the earth and you accomplish the precision of 90 degrees of the edge from the vertical position.

What is horizontal drilling?

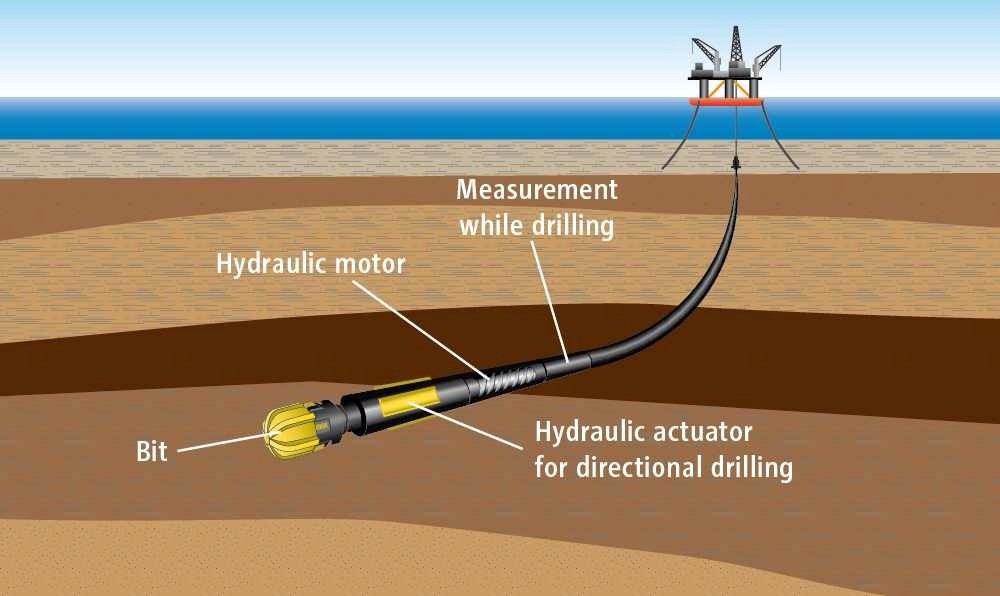

Even penetrating is essentially a boring procedure which enables you to bore at various edges. It works with a twist close to the bit with the assistance of steerable mud engine. This procedure expands the aggregate profitability in the extraction of oils and gases than vertical boring.

It empowers the diggers to penetrate a huge number of foot underneath the world’s hull. It is in charge of the steady increment in the straightforwardness and productivity in the mining business.

With the execution of flat boring presently there is no need of additional burrowing of wells. On having a few locales from even penetrating may possibly liken its efficiency with twenty vertical wells. Such boring decreases the well-being impacts on the people groups living close-by. Execution of level boring is profiting in profitability and making a more secure mining air.

Working of the Horizontal Drilling-

As the name recommends, level or directional penetrating permits boring in various ways. In the entire procedure, the twist guides the bit to move in the specific heading from the genuine wellbore pivot. On accomplishing the fitting point the excavators pivot the penetrate string including the curve. They need to guarantee that the boring tool does not bore in an alternate heading.

Like the vertical well, mineworkers bore the gap to the most profound new water source. Moment concrete comes being used to seal the crisp water source to forestall sullying. The vertical penetrating procedure proceeds till they achieve the kickoff point. until this point, the procedure is same as the vertical boring.

Presently by utilizing steerable mud engine, the bend is made to accomplish the level course and to penetrate toward this path. Diggers perform stumbling funnel to supplant the bit. After fruitful penetrating, concrete packaging is important to anchor the well from leaking gases. Mineworkers utilize puncturing weapon to shoot gaps in the packaging and perform water driven breaking. These breaks enable the gas to course through the well and mineworkers gather it in stores over the ground.