EXHAUST GAS RECIRCULATION (EGR) SYSTEM: WORKING PRINCIPLE, DESIGN AND BENEFITS

Diesel Engines will, in general, transmit higher Nitrogen Oxide (NOx) which is hurtful to people. This is a direct result of high temperatures in the motor chambers on account of higher pressure proportion. To control and diminish the NOx, producers utilize ‘Fumes Gas Recirculation’ innovation in motors.

The term EGR represents Exhaust Gas Recirculation. It is a piece of cutting edge diesel motor vehicles which diminishes the Nitrogen Oxide (NOx) outflows. Fumes Gas Recirculation is the strategy utilized for lessening the nitrogen oxide in both the inner burning diesel motors and also petroleum motors.

WORKING PRINCIPLE

The fumes gas, added to the fuel, oxygen, and ignition items, builds the explicit warmth limit of the barrel substance, which brings down the adiabatic fire temperature.

In an average car start touched off (SI) motor, 5% to 15% of the fumes gas is directed back to the admission as EGR. The greatest amount is constrained by the need of the blend to support a nonstop fire front amid the ignition occasion; extreme EGR in inadequately set up applications can cause failures to discharge and halfway copies. Despite the fact that EGR does quantifiably moderate burning, this can generally be adjusted for by propelling flash planning. The effect of EGR on motor productivity to a great extent relies upon the explicit motor plan, and once in a while prompts a bargain among effectiveness and NOx outflows. A legitimately working EGR can hypothetically build the productivity of gas motors by means of a few instruments:

• Reduced throttling misfortunes. The expansion of latent fumes gas into the admission framework implies that for a given power yield, the throttle plate must be opened further, bringing about expanded bay complex weight and diminished throttling misfortunes.

• Reduced warmth dismissal. Brought down pinnacle ignition temperatures not just decreases NOx development, it additionally lessens the loss of warm vitality to burning chamber surfaces, leaving increasingly accessible for change to mechanical work amid the extension stroke.

• Reduced substance separation. The lower crest temperatures result in a greater amount of the discharged vitality staying as sensible vitality close TDC (Top Dead-Center), as opposed to being bound up (from the get-go in the development stroke) in the separation of ignition items. This impact is minor contrasted with the initial two.

EGR is normally not utilized at high loads since it would lessen top power yield. This is on the grounds that it diminishes the admission charge thickness. EGR is likewise excluded out of gear (low-speed, zero load) since it would cause insecure ignition, bringing about harsh inert.

Since the EGR framework recycles a part of fumes gases, after some time the valve can wind up obstructed with carbon stores that keep it from working appropriately. Obstructed EGR valves can some of the time be cleaned, however substitution is fundamental if the valve is defective.

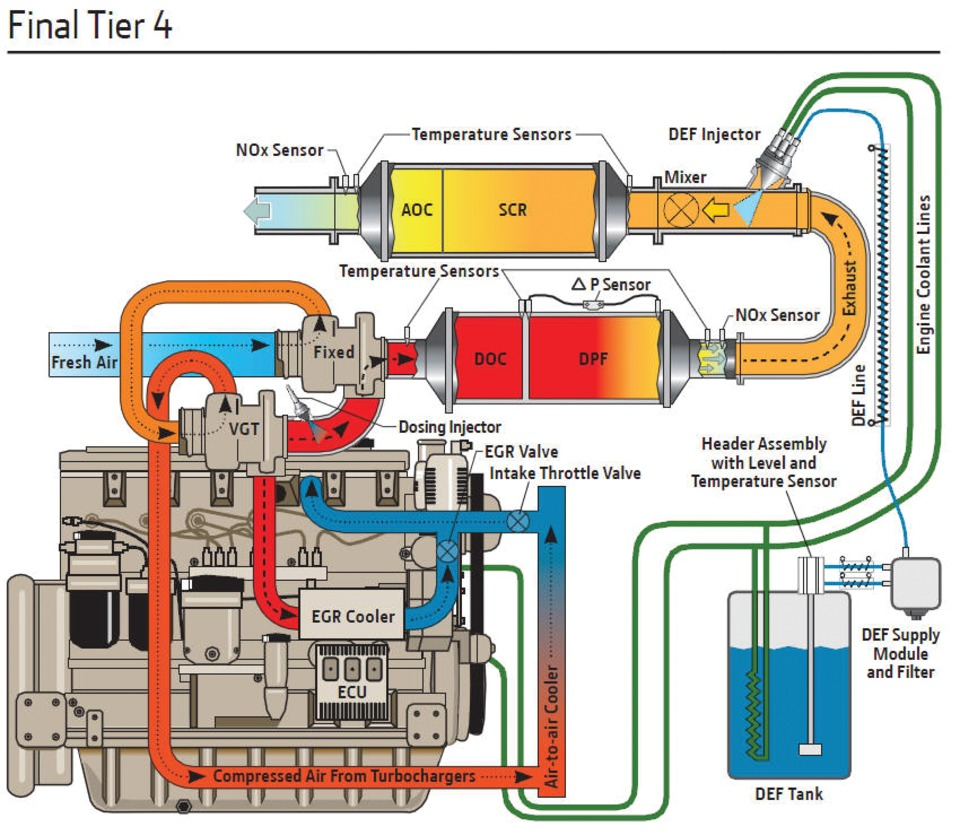

Plan

A vacuum controlled EGR valve manages the measure of fumes gases conceded into the barrels. It comprises of a spring-stacked vacuum stomach. It connects to a metered valve which controls the section of the fumes gases. Ported vacuum from an adjusted flag port situated over the throttle valve associates with the EGR vacuum chamber.

At lingering, the EGR valve is in the shut position as a result of the spring weight and lower ported vacuum. The specialists structured it so provided that the fumes gases recycle at the lingering, at that point it would cause harsh/unpredictable sitting. After opening of the throttle applies the ported vacuum and step by step opens the decreased valve. This causes the fumes gas to stream into the admission complex.

Be that as it may, when the throttle opens completely, there is no vacuum in the admission complex. Along these lines, it shuts the decreased valve and prevents the fumes gases from entering the admission complex.

Advantages

The Exhaust Gas Recirculation framework recycles a piece of the fumes gas once more into the motor barrels through the ignition chamber. The rationale behind the EGR framework is exceptionally basic. The fumes gas is more sweltering than the outside air sucked by the motor. In this way, the fumes gas fundamentally diminishes the substance of the chamber for ignition. As a result of the nonattendance of oxygen (O2), the fumes gases have nothing to consume as they contain neither fuel nor oxygen particles.

Along these lines, it results in lower warm release and barrel temperatures. It lessens the development of nitrogen oxide (NO2) also. The torpid fumes gas present in the chamber likewise restricts the pinnacle temperatures. It additionally diminishes the misfortune that emerges on account of throttling in petroleum motors while enhancing the motor life by lessening the barrel temperatures. The three-organize exhaust system further decreases the NOx to satisfactory dimensions.

LIMITATIONS

The architects planned the EGR framework so that it recycles the fumes gases just when the motor structures the Nitrogen Oxide (NOx). In this manner, the EGR framework DOES NOT influence the ‘Full-Load’ task. The Exhaust Gas Recirculation framework likewise has a warm control valve in the vacuum line which keeps the activity of EGR at lower motor temperatures. This framework is valuable particularly in the diesel motors where the exhaust system can’t animate the concoction decrease because of high oxygen substance. In this way, the NOx discharge continues as before in such conditions.