Lathe Machine | Parts, Types, Operations, Limitations

In this article we have examined Lathes and its distinctive kinds. In this article you will likewise find out about working, diverse applications and machine parts.

In the wake of perusing this article you would have the capacity to comprehend machine as an apparatus (Manufacturing Science) betterly.

What is a lathe?

A machine is presumably one of the most established machine device created by individuals. It is commonly used to create round and hollow surfaces however various sorts of surfaces can likewise be produced by them.

A machine is an easy to utilize machine device and has diverse sorts (as per use)

Sorts of machine

Types of lathe

- Centre lathe

- Bench lathe

- Tool room lathe

- Special purpose lathe

- Copying lathe

- Gap bed lathe

- Hollow spindle lathe

- Capstan and turret lathe

- Automatic lathes

Centre lathe is most normal and is utilized for universally useful. They can perform different tasks however has less profitability

Tool room lathes are commonly utilized for device

Special purpose lathe machines are utilized to perform explicit activities which can’t be by and large performed by Center machine.

Capstan, Turret and Automatic machines are utilized for high creation rates. They are commonly utilized for uncommon reason. They can likewise run unattended if essential.

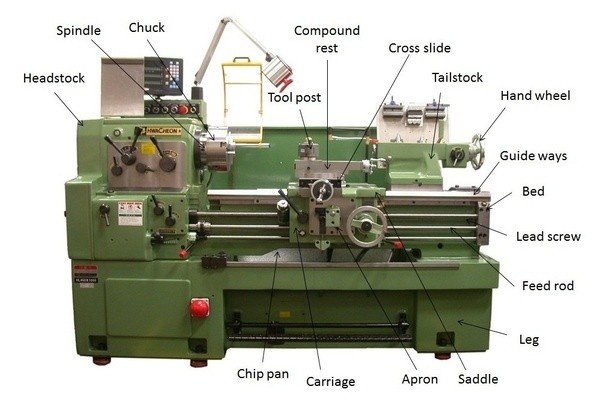

lathe machine parts

- Headstock

- Shaft

- Feed switch gear box

- Compound rest and slide

- Device post

- Carriage (or Saddle)

- Cross-slide

- Tailstock

- Feed bar

- Bed

- Lead screw

Types of tools that can be used in lathes

There are numerous devices which are utilized to produce explicit sort of surfaces. They are

- Parting tool

- Turning tool

- Right hand turning tool

- Left hand turning tool

- Radius turning tool

- Thread cutting tool

- Chamfering form tool

- Internal turning tool

- Internal facing tool

- Recess or groove making

- Internal threading tool

Tasks that can be performed in a Center machine

- Turning

- Confronting

- Knurling

- Separating

- Penetrating

- Exhausting

To build the abilities of a Center machine and to perform different tasks following connections can be utilized

- Milling attachment

- Grinding attachment

- Copy turning attachment

- Radius turning attachment

Limitations of Centre lathe

- Setting time for holding work is high

- Just a single apparatus can be utilized for the most part at once

- Inert time in the middle of the activity is high