Starting System: Components and How it Works

The starter motor is an electric motor that pivots your motor so as to permit the start and fuel infusion frameworks to start the motor’s activity under its own capacity. Commonly, the starter is an extensive electric engine and stator loop mounted to the base (for the most part to the other side) of the vehicle’s transmission chime lodging where it interfaces with the motor itself. The starter has gears that work with an expansive flywheel adapted on the rear of the motor, which turns the focal wrench shaft. Since this is a great deal of physical weight and erosion to survive, starter engines are commonly incredible, rapid engines and utilize a start loop to increase their capacity before lock in.

Components of starting system

- Battery

The car battery, otherwise called a lead-corrosive stockpiling battery, is an electrochemical gadget that produces voltage and conveys current. In a car battery we can switch the electrochemical activity, along these lines energizing the battery, which will at that point give us numerous long stretches of administration. The reason for the battery is to supply flow to the starter engine, give flow to the start framework while wrenching, to supply extra flow when the interest is higher than the alternator can supply and to go about as an electrical store.

- Ignition Switch

The start switch enables the driver to disseminate electrical flow to where it is required. There are by and large 5 key switch positions that are utilized:

- Bolt All circuits are open ( no current provided) and the guiding wheel is in the bolt position. In a few vehicles, the transmission switch can’t be moved in this position. In the event that the guiding wheel is applying weight to the locking system, the key may be difficult to turn. In the event that you do encounter this kind of condition, take a stab at moving the controlling wheel to evacuate the weight as you turn the key.

- Off-All circuits are open, however the guiding wheel can be turned and the key can’t be extricated.

- Run-All circuits, aside from the starter circuit, are shut (current is permitted to go through). Current is provided to everything except the starter circuit.

- Begin Power is provided to the start circuit and the starter engine as it were. That is the reason the radio quits playing in the begin position. This situation of the start switch is spring stacked with the goal that the starter isn’t locked in while the motor is running. This position is utilized quickly, just to initiate the starter.

- Adornment Power is provided to everything except the start and starter circuit. This enables you to play the radio, work the power windows, and so forth while the motor isn’t running.

Most start switches are mounted on the directing segment. A few switches are really two separate parts;

- The bolt into which you embed the key. This segment likewise contains the component to bolt the guiding haggle.

- The switch which contains the genuine electrical circuits. It is generally mounted over the directing section simply behind the dash and is associated with the bolt by a linkage or bar.

- Neutral Safety Switch

This switch opens (denies current to) the starter circuit when the transmission is in any rigging however Neutral or Park on programmed transmissions. This switch is regularly associated with the transmission linkage or straightforwardly on the transmission. Most autos use this equivalent change to apply current to the back up lights when the transmission is placed backward. Standard transmission autos will associate this change to the grip pedal with the goal that the starter won’t connect with except if the grasp pedal is discouraged. In the event that you find that you need to move the shifter far from park or impartial to inspire the vehicle to begin, it typically implies that this switch needs modification. On the off chance that your vehicle has a programmed leaving brake discharge, the impartial security switch will control that work moreover.

- Starter Relay

A transfer is a gadget that permits a little measure of electrical flow to control a lot of flow. A car starter utilizes a lot of current (250+ amps) to begin a motor. If we somehow managed to enable that much current to experience the start switch, we would require a vast switch, as well as every one of the wires would need to be the extent of battery links (not extremely handy). A starter transfer is introduced in arrangement between the battery and the starter. A few vehicles utilize a starter solenoid to achieve a similar motivation behind permitting a little measure of current from the start change to control a high current spill out of the battery to the starter. The starter solenoid at times likewise mechanically draws in the starter outfit with the motor.

Battery Cables

Battery links are expansive distance across, multistranded wire which convey the high current (250+ amps) important to work the starter engine. Some have a littler wire patched to the terminal which is utilized to either work a littler gadget or to give an extra ground. At the point when the littler link consumes, this demonstrates a high obstruction in the overwhelming link. Care must be taken to keep the battery link closes (terminals) spotless and tight. Battery links can be supplanted with ones that are marginally bigger however never littler.

- Starter Motor

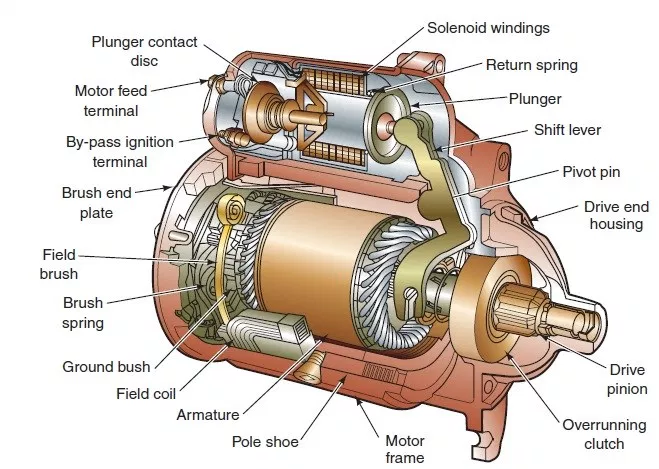

The starter engine is an incredible electric engine, with a little rigging (pinion) connected as far as possible. Whenever actuated, the apparatus is coincided with a bigger rigging (ring), which is connected to the motor. The starter engine at that point turns the motor over with the goal that the cylinder can attract a fuel/air blend, which is then touched off to begin the motor. At the point when the motor begins to turn quicker than the starter, a gadget called an invading grip (bendix drive) naturally separates the starter outfit from the motor apparatus.

Working Principle.

To make a motor begin it must be turned at some speed, with the goal that it sucks fuel and air into the chambers, and packs it.

The ground-breaking electric starter engine does the turning. Its pole conveys a little pinion (outfit wheel) which connects with an expansive apparatus ring around the edge of the motor flywheel.

In a front-motor format, the starter is mounted down and out close to the back of the motor.

The starter needs an overwhelming electric flow, which it draws through thick wires from the battery. No standard hand-worked switch could switch it on: it needs a substantial change to deal with the high current.

The change must be turned on and off rapidly to evade risky, harming starting. So a solenoid is utilized – a game plan where a little switch turns on an electromagnet to finish the circuit.

The starter switch is normally worked by the start key. Turn the key past the ‘start on’ position to bolster current to the solenoid.

The start switch has an arrival spring, so that when you discharge the key it springs back and kills the starter switch.

At the point when the change encourages current to the solenoid, the electromagnet pulls in an iron pole.

The development of the bar closes two substantial contacts, finishing the circuit from the battery to the starter.

The bar likewise has an arrival spring – when the start switch quits bolstering current to the solenoid, the contacts open and the starter engine stops.

The arrival springs are required in light of the fact that the starter engine must not turn more than it needs to so as to begin the motor. The reason is halfway that the starter utilizes a great deal of power, which rapidly keeps running down the battery.

Additionally, if the motor begins and the starter engine remains drew in, the motor will turn the starter so quick that it might be seriously harmed.

The starter engine itself has a gadget, called a Bendix adapt, which connects with its pinion with the apparatus ring on the flywheel just while the starter is turning the motor. It withdraws when the motor grabs speed, and there are two different ways by which it does as such – the dormancy framework and the pre-drawn in framework.

The latency starter depends on the dormancy of the pinion – that is, its hesitance to start to turn.

The pinion isn’t settled inflexibly to the engine shaft – it is strung on to it, similar to a uninhibitedly turning nut on an extremely coarse-string fastener.

Envision that you all of a sudden turn the fastener: the idleness of the nut shields it from turning without a moment’s delay, so it moves along the string of the screw.

At the point when an inactivity starter turns, the pinion moves along the string of the engine shaft and connects with the flywheel outfit ring.

It at that point achieves a stop toward the finish of the string, starts to turn with the pole thus turns the motor.

When the motor begins, it turns the pinion quicker than its very own starter-engine shaft. The turning activity screws the pinion down its string and out of commitment.

The pinion returns so brutally that there must be a solid spring on the pole to pad its effect.

The fierce commitment and separation of an idleness starter can cause substantial wear on the rigging teeth. To defeat that issue the pre-connected with starter was presented, which has a solenoid mounted on the engine.

There’s something else entirely to a vehicle starter framework: As well as exchanging on the engine, the solenoid additionally slides the pinion along the pole to draw in it.

The pole has straight splines as opposed to a Bendix string, so the pinion dependably turns with it.

The pinion is carried into contact with the toothed ring on the flywheel by a sliding fork. The fork is moved by a solenoid, which has two arrangements of contacts that close in a steady progression.

The primary contact supplies a low present to the engine with the goal that it turns gradually – sufficiently far to give the pinion teeth a chance to lock in. At that point the second contacts close, sustaining the engine a high current to turn the motor.

The starter engine is spared from over-speeding when the motor begins by methods for a freewheel grip, similar to the freewheel of a bike. The arrival spring of the solenoid pulls back the pinion from commitment.