Power Screw | Applications, Types, Advantages, Disadvantages, Parts

What is a power screw?

A power screw is a mechanical part which is utilized to change over revolving movement into the direct movement.

At times a power screw is otherwise called interpretation screw.

It utilizes helical movement of screw to transmit the power as opposed to holding the parts together.

Lead and contribute screws

Applications of power screws

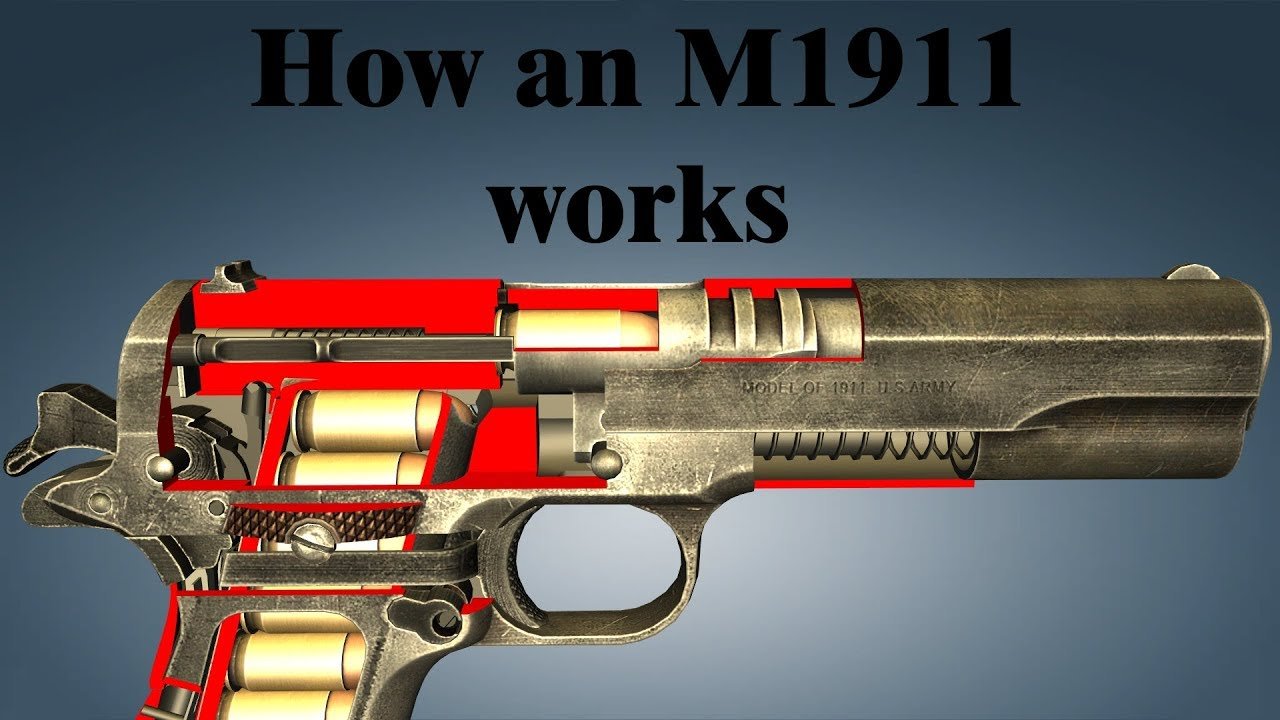

It is utilized to raise the heap e.g. screw jack

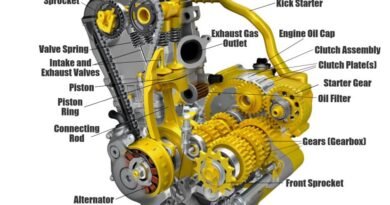

It is utilized to get an exact movement e.g. lead screw of machine

It is utilized to stack an example e.g. all inclusive testing machine

It is utilized to cinch a workpiece e.g. bad habit

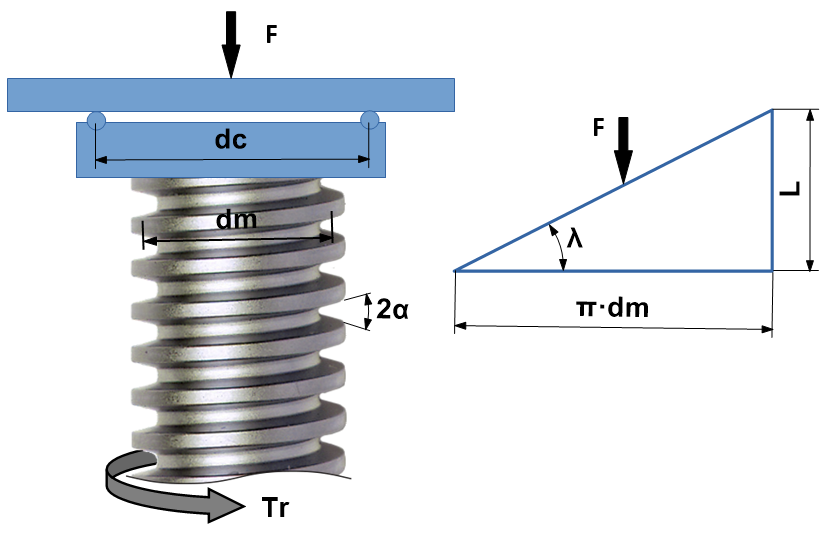

Parts of power screws

A power screw has following three sections.

It comprises a Screw

It comprises a Nut

It comprises a section which holds either nut or screw set up

Contingent upon the sort of holding plan control screws can be isolated into two sections

Fasten moves pivotal course and nut kept stationary. E.g. screw jack and bad habit

Nut moves in hub course and screw kept stationary. E.g. lead screw of a machine.

Advantages offered by power screws

It has vast load conveying limit

It very well may be planned with self-locking property. Screw jack is the ideal case of this.

In view of few sections it is modest and dependable

It gives smooth and quiet administration

It requires no support

It gives extremely exact movement which is required in machine instrument applications

It gives high mechanical favorable position consequently utilized in screw jacks, clasps, valves and indecencies.

Its assembling is simple and does not required any specific apparatus

It is easy to plan

In general elements of intensity tighten are little which results smaller development

Disadvantages of power screws

It has poor productivity

Because of high grating, wear is a significant issue in power screws

There are two kinds of uses of intensity screws

Where high proficiency is wanted. E.g. lead screws and presses

Where low effectiveness is wanted. E.g. screws jacks, braces and indecencies

To expand the proficiency of intensity screws the sliding contact is diminished by moving grating. This essential is utilized in recycling ball screws.

Types of threads used in power screws

Square strings

Trapezoidal strings

Summit strings

Support strings