AIR BRAKE SYSTEM: COMPONENTS, WORKING PRINCIPLE, AND APPLICATIONS

Introduction

Air brake systems are a critical component of modern transportation, particularly in heavy-duty vehicles such as trucks, buses, and trains. These systems use compressed air to safely and reliably stop or slow down a vehicle, making them an essential safety feature for drivers, passengers, and other road users. In this article, we will explore the different types of air brake systems, how they work, and the key components that make them function.

History of Air Brake Systems

The history of air brake systems dates back to the mid-19th century. Prior to this time, trains were equipped with hand brakes, which were operated manually by the train’s crew. This made stopping a train a difficult and dangerous task, especially in emergency situations. In 1868, George Westinghouse, an American inventor, and industrialist, developed the first air brake system for trains. This system allowed the train’s crew to stop the train safely and quickly, even in emergency situations.

The air brake system was a major breakthrough in train safety, and it quickly became popular in the United States and around the world. Over time, air brake systems were adapted for use in other types of vehicles, including trucks and buses. Today, air brake systems are an essential safety feature in many types of heavy-duty vehicles.

Types of Air Brake Systems

There are two main types of air brake systems used in heavy-duty vehicles: drum brakes and disc brakes. Drum brakes are the older of the two technologies and are still in use in many vehicles today. Disc brakes are a newer technology that offers some advantages over drum brakes.

Drum Brakes

Drum brakes consist of a circular drum that is attached to the wheel of the vehicle. Inside the drum are curved brake shoes that are lined with friction material. When the brakes are applied, the brake shoes are forced against the inside of the drum, creating friction that slows down or stops the vehicle.

Drum brakes are simple and reliable, and they are still used in many heavy-duty vehicles today. However, they have some disadvantages compared to disc brakes. For example, drum brakes are more prone to overheating, which can reduce their effectiveness. They are also more difficult to cool down than disc brakes. In addition, drum brakes are more difficult to inspect and service than disc brakes.

Disc Brakes

Disc brakes consist of a flat disc that is attached to the wheel of the vehicle. When the brakes are applied, hydraulic pressure is used to force a pair of brake pads against the disc, creating friction that slows down or stops the vehicle.

Disc brakes offer several advantages over drum brakes. For example, they are less prone to overheating and are easier to cool down. They also offer better stopping power and are easier to inspect and service than drum brakes. However, they are more expensive to manufacture and require more maintenance than drum brakes.

How Air Brake Systems Work

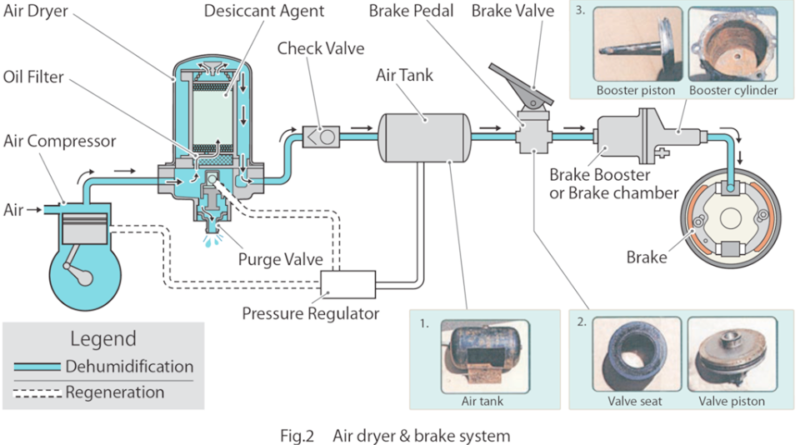

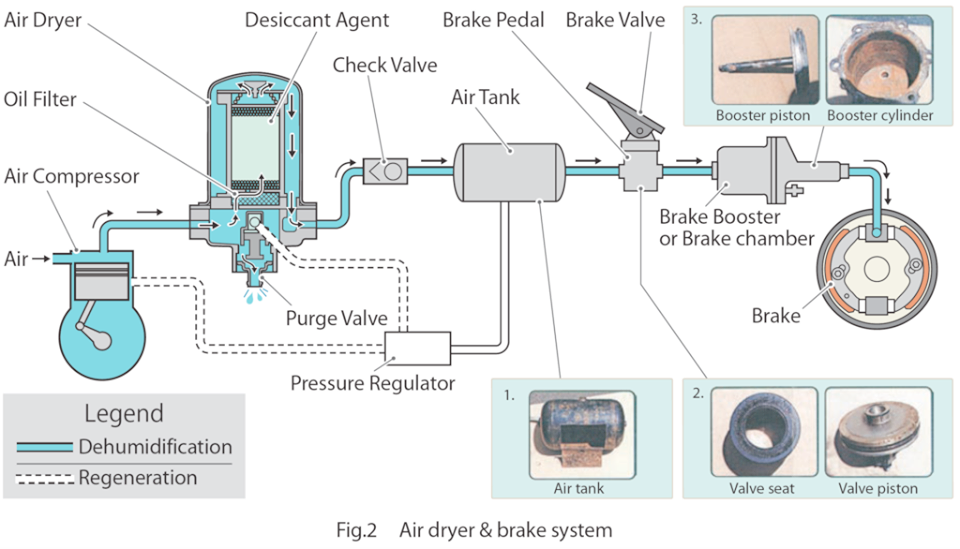

Air brake systems work by using compressed air to apply the brakes. The system consists of several key components, including an air compressor, an air reservoir, a set of brake valves, and a set of brake chambers.

Air Compressor

The air compressor is responsible for compressing air and storing it in the air reservoir. The compressor is typically driven by the engine of the vehicle and is equipped with a governor that regulates the pressure of the compressed air.

Air Reservoir

The air reservoir is a large tank that stores compressed air. It is typically located near the compressor and is connected to it by a set of hoses