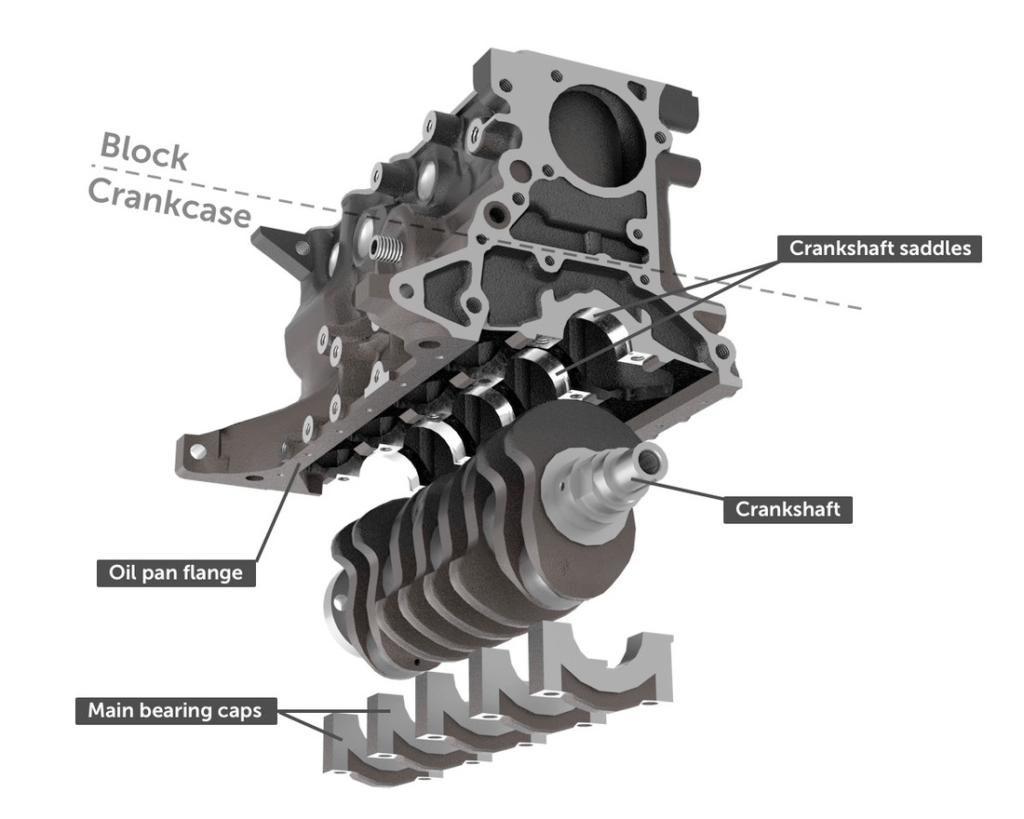

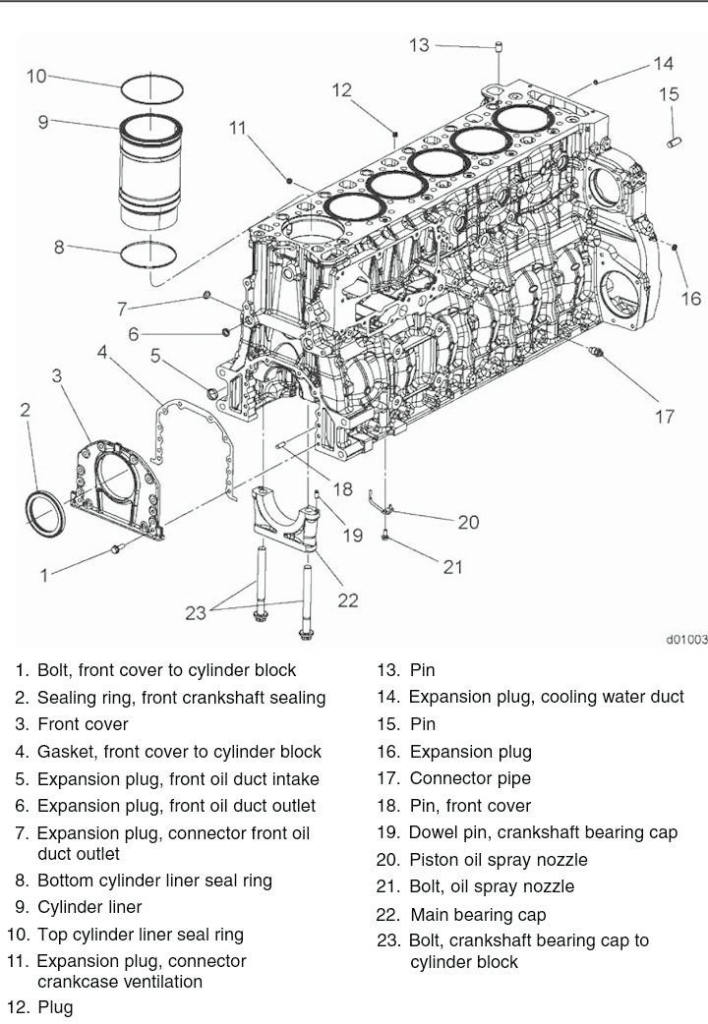

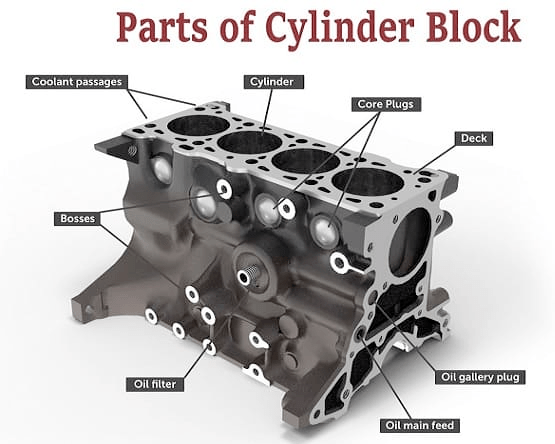

Exploded view of the cylinder block

What is cylinder block assembly?

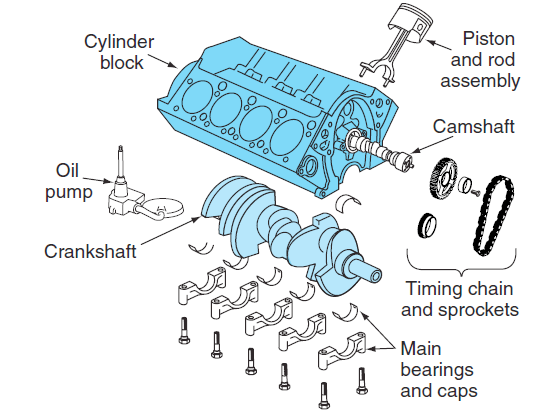

The cylinder block is the largest part of the engine and is the base to which many other parts are assembled or attached. The upper part of the block carries the cylinders and pistons, and the lower part forms the crankcase which supports the crankshaft.

![]() What is the purpose of the cylinder block?

What is the purpose of the cylinder block?

The cylinder block is one of your engine’s central components. It plays a key role in the lubrication, temperature control, and stability of the engine and it has to be of the highest quality so there is no room for shortcuts.

![]() How are cylinder blocks manufactured?

How are cylinder blocks manufactured?

Manufacturing of engine blocks is mainly done using sand casting, although die casting is also used it is more cost-effective as the die wears out easily due to the high temperature of the molten metal. The casted engine block is then machined to get the surface finish and coolant passages.

![]() What are the types of cylinder blocks?

What are the types of cylinder blocks?

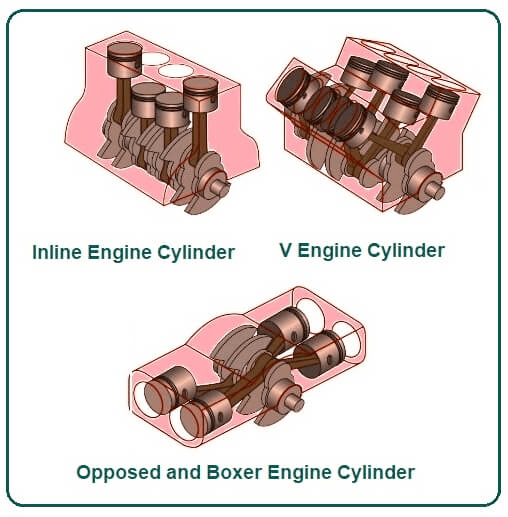

Types of Engine Block / Types of Cylinder Block

– V Engine Cylinder. It is the popular engine cylinder type and is widely used nowadays.

– Inline Engine Cylinder. Inline engine cylinder block, a series of cylinders is arranged in a way that they run in a single line.

– Opposed Engine Cylinder / Boxer Engine Cylinder.

![]() What are the parts of the cylinder block and its function?

What are the parts of the cylinder block and its function?

The block supports the components of the engine including the auxiliary devices. Devices such as A/C compressor, alternator, intake and exhaust manifold, etc. It features the parts for the lubrication circle such as the oil pan, oil pump, oil filter, etc. It also, play a vital role in the cooling circuit.

![]() What material is used for cylinder blocks?

What material is used for cylinder blocks?

Cylinder blocks are normally made of cast iron or aluminum alloy. The aluminum block is much lighter. Various types of materials are combined to increase strength.