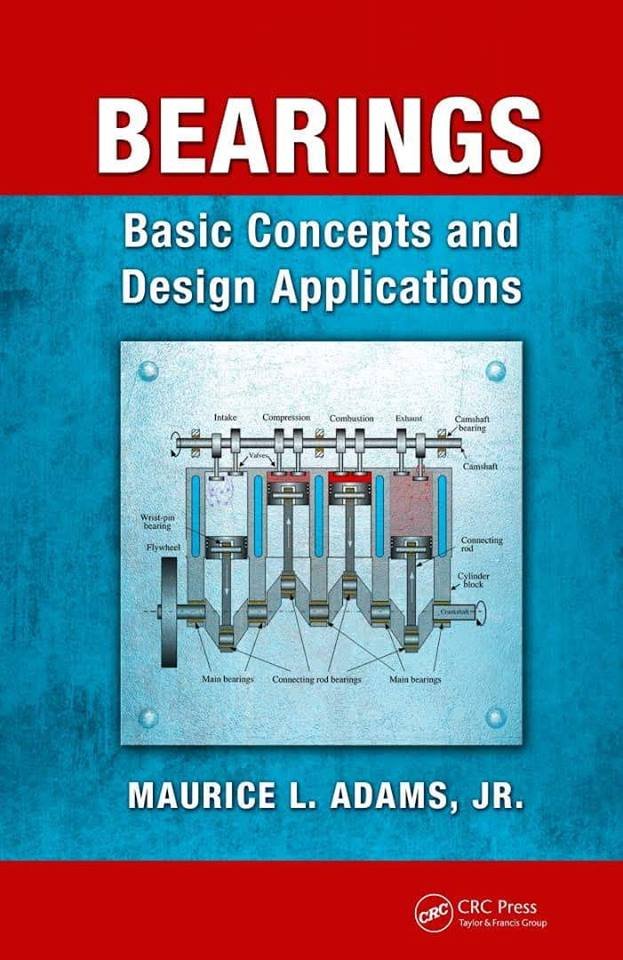

Bearings basic concepts and design applications

Bearings basic concepts and design applications

Pages: 311

Table of contents:

All machines and mechanisms have parts connected to each other that are in relative motion. The components that connect those parts in relative motion are called bearings and thus are at the heart of all machines and mechanisms in the modern world.

One widely recognized machine type is the automotive engine, which has crankshaft main bearings, rod bearings, wrist-pin bearings, and valve/camshaft bearings.

Vehicles also need bearings for the wheels, transmission internal components, steering mechanism, and suspension components. Similarly, a wide variety of bearings are also needed in aircraft, ships, power turbines, pumps, manufacturing machine tools, and home appliances.

In performing their operating function, bearings often must reliably sustain significant interactive forces between the parts they connect. With those significant connection forces, bearings often also simultaneously sustain significantly high relative sliding velocities between the parts they connect.

In the presence of simultaneous significant sliding velocities and connection forces, sliding friction between the mating bearing parts naturally results. As is well known, rubbing friction between parts in relative sliding motion may cause wear, often an important bearing design selection factor.

The sliding friction forces also convert mechanical energy into heat. So, bearings may have to sustain elevated temperatures from that friction heat production. Furthermore, when bearing components heat up they may experience significant thermal expansion and distortion.

In some bearing types, that thermal expansion can be comparable

That energy efficiency factor often plays a major role in determining the optimum bearing type for a given application.

When bearings wear out the need to be replaced, so the ease of replacement can be a major design consideration, for example, labor costs accrued in auto repairs and industrial machinery maintenance. Related to this, the bearing cost and the need to have replacement bearings as part of a spare parts inventory are important factors.

You can download this book from the first link on website comments Like this photo

if you have any question leave a comment .

Download Link: https://drive.google.com/file/d/1FZS1SIf5O4GMPqSAih0G-yLtQH0aqJy_/view