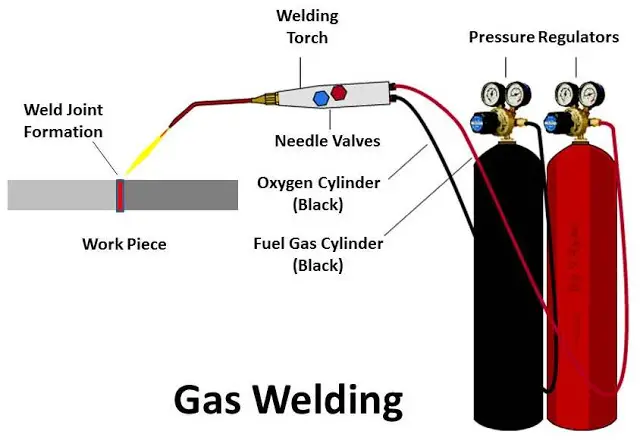

Gas Welding : Principle, Working, Equipment, Application, Advantages and Disadvantages

Principle

Gas welding is the most vital kind of welding process. It is finished by consumption of fuel gases with the assistance of oxygen which frames a concentrated fire of high temperature. This fire straightforwardly strikes the weld zone and melts the weld surface and filler material. The dissolved piece of welding plates diffused in each other and make a weld joint subsequent to cooling. This welding strategy can be utilized to join the greater part of normal metals utilized in day by day life.

Equipment:

Welding Torch:

Welding lights are most critical piece of gas welding. Both the fuel gas and oxygen at reasonable weight bolstered through hoses to the welding light. There are valves for every ga witch control the stream of gases inside the light. The two gases blended there and frame a combustible blend. These gases touch off to consume at the spout. The fire move through spout and strikes at welding plates. The spout thickness relies upon the span of the welding plates and material to be welded.

Oxygen Cylinder:

For legitimate consuming of fuel, proper measure of oxygen required. This oxygen provided by an oxygen chamber. A dark line is utilized to show oxygen chamber.

Fuel Gas Cylinder:

Gas chamber is filled either by oxy acetylene gas, hydrogen gas, gaseous petrol or other combustible gas. The fuel gas choice is relies upon the welding material. For the most part oxy acetylene gas is utilized for all universally useful of welding. Regularly these chambers have Maroon line to demonstrate it. The fuel gases goes through it.

Pressure regulator:

Both oxygen and fuel gases are filled in chamber at high weight. These gases can’t use at this high weight for welding work so a weight controller is utilized between stream. It supplies oxygen at weight around 70 – 130 KN/M2 and gas at 7 – 103 KN/M2 to the welding light.

Goggles and Gloves:

These are use for security motivation behind welder. It shields eyes and hand from radiation and fire of flame.

Working:

Gas welding process is very less difficult contrast with curve welding. In this procedure all the gear are associated cautiously. The gas barrel and oxygen chamber

associated with the welding light through weight controllers. Presently the manage weight of gas and oxygen provided to the light where they legitimately blended. The fire is touched off by a striker. Take care the tip of light is pointing descending. Presently the fire is controlled through valves arranged in welding light. The fire is set at common fire or carburizing fire or oxidizing fire as indicated by the welding condition. Presently the welding light moved along the line where joint to be made. This will liquefy the interface part and go along with them for all time.

Application:

- It is utilized to join thin metal plates.

- It can used to join both ferrous and non-ferrous metals.

- Gas welding for the most part utilized in creation of sheet metal.

- It is generally utilized in car and flying machine enterprises.

Advantages:

- It is anything but difficult to work and portion not required high aptitude administrator.

- Hardware cost is low contrast with other welding forms like MIG, TIG and so on.

- It very well may be utilized at site.

- Hardware’s are more convenient than other kind of welding.

- It can likewise be utilized as gas cutting.

Disadvantages:

- It gives low surface wrap up. This procedure needs a completing activity in the wake of welding.

- Gas welding have vast warmth influenced zone which can cause change in mechanical properties of parent material.

- Higher wellbeing issue because of exposed fire of high temperature.

- It is Suitable just for delicate and thin sheets.

- Moderate metal joining rate.

- No protecting region which causes all the more welding imperfections.