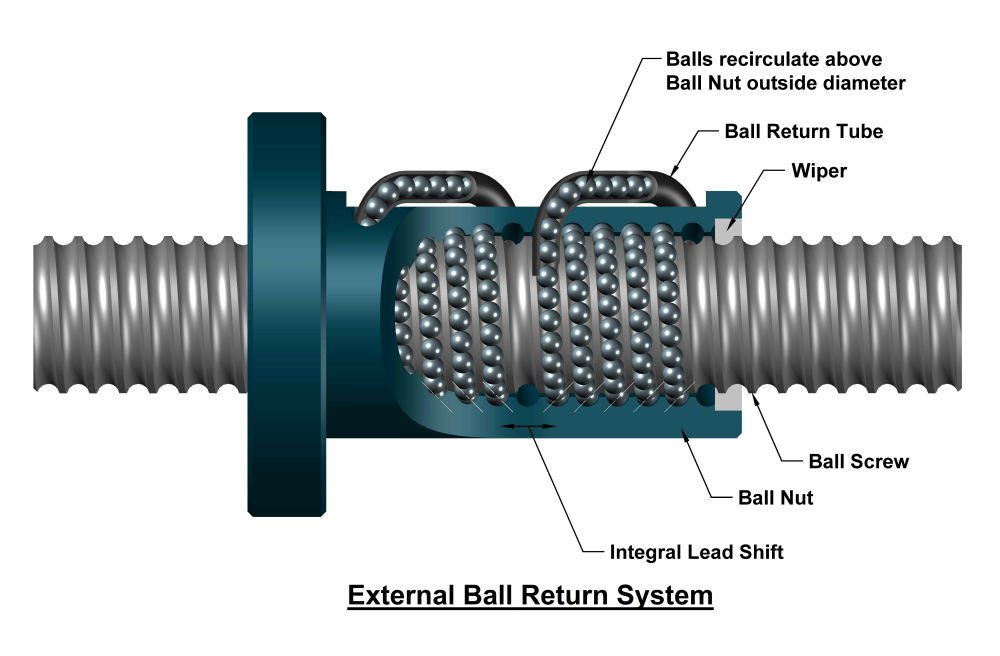

Recirculating ball screw

A Recirculating ball screw comprises a screw, a nut and a progression of balls.

The contrast between a Recirculating ball screw and a power tighten is that previous the sliding grating kicks it into high gear erosion.

Since moving is not exactly sliding grating

Recirculating ball screw has proficiency of intensity exchange.

The strings of and nut

Recirculating ball screw are circle with the goal that they can oblige moving balls.

ball screw is otherwise called metal ball screw or essentially ball screw.

There is no warmth age in recycling ball screw because of irrelevant grinding and they can be utilized at high accelerates to 10 m/min.

Advantages of recirculating ball screw

Contrasted with power screw they offer after favorable circumstances.

- They have high productivity (approx. 90%), contrasted with power screw (approx. 40%)

- No stick and slip marvel which results in sturdiness

- It is for all intents and purposes wear free

- They require Less beginning torque

- No warmth age amid task

- They can be utilized for fast tasks

- They can be effectively preloaded to dispose of kickback

- They have extremely smooth and quiet task

- They have high unwavering quality and solidness

- Their heap conveying limit is more than power screw of a similar size

Disadvantages of recirculating ball screw

Contrasted with power screw they offer after drawbacks.

- They are substantially more expensive

- Clasping of screw is not kidding issue at basic speed

- They require high level of tidiness

- They require thin film oil for attractive activity

- They can have vibrations

- They require intermittent redesiging to keep up their productivity

- They don’t make them bolt properties

Uses of Recirculating ball screw

- Machine apparatuses controls

- Utilized in mechanical technology where exact development is essential

- Healing facility beds agents

- Flying machine landing gear retractors

- X-Y recorders of CNC machines

- Power actuators

- Car guiding apparatuses