Gear Terminology: Basic Definition Used in Gear

Today we will examine

Gear Terminology:

The accompanying terms, which are for the most part used to depict a rigging, are as pursue.

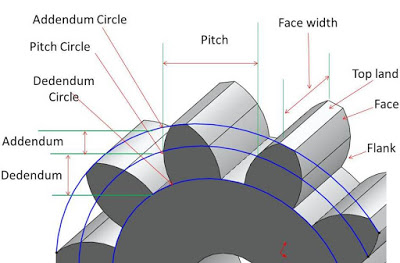

Face of tooth:

It is characterized as the surface of the tooth over the pitch circle is known as face.

Flank of tooth:

The surface of the tooth underneath the pitch circle is known as flank.

Top land:

The best most surface of the tooth is known as the best place where there is the tooth.

Face width:

Width of the tooth is known as face width.

Pitch Circle:

It is a nonexistent circle which is in unadulterated moving activity. The movement of the rigging is depict by the pitch circle movement.

Pitch Circle measurement:

The measurement of the pitch hover from the focal point of the rigging is known as pitch circle distance across. The rigging measurement is portrayed by its pitch circle width.

Pitch point:

At the point when the two apparatuses are in contact, the basic purpose of both of pitch hover of cross section gears is known as pitch point.

Pressure angle or angle of obliquity:

Weight edge is the edge between basic ordinary to the pitch hover to the normal digression to the pitch point.

Addendum:

Separation between the pitch hover to the highest point of the tooth outspread way is known as addendum.

Dedendum:

Separation between the pitch hover to the base of the tooth spiral way, is known as dedendum of the rigging.

Addendum circle:

The hover goes from the highest point of the tooth is known as addendum circle. This circle is concentric with pitch circle.

Dedendum circle:

The hover goes from the base of the tooth is known as dedendum circle. This circle is likewise concentric with pitch circle and addendum circle.

Round pitch:

The separation between a point of a tooth to a similar purpose of the adjoining tooth, estimated along periphery of the pitch circle is known as roundabout pitch. It is assumes measure job in rigging coinciding. Two riggings will work together accurately if and just they have same round pitch.

Polar pitch:

The proportion of the quantity of teeth to the width of contribute circle millimeter is known as polar pitch.

Module:

The proportion of the contribute circle width millimeters to the aggregate number of teeth is known as module. It is corresponding of the polar pitch.

Clearance:

At the point when two riggings are in lattice condition, the outspread separation from best of a tooth of one apparatus to the base of the tooth of another apparatus is known as leeway. The hover goes from the highest point of the tooth in cross section condition is known as leeway edge.

Total depth:

The aggregate of the addendum and dedendum of a rigging is known as aggregate profundity. It is the separation between addendum hover to the dedendum hover measure along spiral heading.

Working depth:

The separation between addendum hover to the freedom hover estimated along spiral bearing is known as working profundity of the rigging.

Tooth thickness:

Separation of the tooth estimated along the circuit of the pitch circle is known as tooth thickness.

Tooth space:

Separation between the two nearby tooth estimated along the outline of the pitch circle is known as the tooth space.

Backfire:

It is the contrast between the tooth thickness and the tooth space. It counteracts sticking of the apparatuses in lattice condition.

Profile:

It is the bended framed by the face and flank is known as profile of the tooth. Rigging tooth are for the most part have cycloidal or involute profile.

Filet range

Way of contact:

The bended followed by the purpose of contact of two teeth frame starting as far as possible of commitment is known as way of contact.

Curve of contact:

It is the bend followed by the pitch point frame the start as far as possible of commitment is known as curve of contact.

Circular segment of methodology:

The part of the way of contact from start of commitment to the pitch point is known as circular segment of methodology.

Bend of break:

The bit of the way of contact shape pitch point as far as possible of the commitment is known as circular segment of break.