Today we will talk about clutch. In my past we have examined about sorts of clutches. We realize that as indicated by the connecting with impact, the clutch has two sorts. The first is certain dislodging clutch and the other one is friction clutch. Each clutch requires a holding power which deals with legitimate drawing in and separating grasp. This power is now and again gotten by spring put away vitality and at times by another wellspring of vitality. An electromagnetic clutch is likewise a grinding clutch which utilizes electromagnetic power to connect with and withdraw the clutch.

In the wake of perusing this section, a few inquiries emerges in our psyche.

- What is electromagnetic power?

- How a clutch utilizes this power to connect with and separate grasp?

- How a down to earth electromagnetic clutch works?

You can discover reply of those inquiries in this article.

What is Electromagnetic power?

It is an essential power related with electric and attractive field. In basic words, two particles pulled in towards one another because of electric charge or attraction is called electromagnetic power. It is a more grounded than gravity however more fragile than atomic power. This power comes without hesitation when two electric charges or attractive particles comes into contact. Any magnet draws in iron pieces towards it because of electromagnetic power.

Electromagnetic Clutch:

Principle

Before examining about electromagnetic grip first you should think about essential things of grasp. Grasp is a gadget which connect with or separate two shafts called driving shaft or motor shaft and driven shaft or rigging box shaft. A basic fundamental grasp comprise two weight plates, one is associated with motor shaft and other one with gearbox. The weight drive is connected by the spring game plan which constrained these plates towards one another when the grasp pedal isn’t squeezed. There is a grinding plate between both of these weight plates. At the point when the motor shaft pivots, it makes turn the apparatus shaft because of contact compel between them. At the point when the driver press the grip pedal, both weight plate free contact with one another and grasp is in withdraw position. This is fundamental of any grasp. All rubbing grips take a shot at same guideline. An electromagnetic grip is likewise a contact grasp however it utilizes attractive power instead of spring power to draw in and withdraw the grasp. It likewise comprise two grip plates (Rotor and Hub). One of them is associated with the electric circuit. At the point when the power goes through this plate, it changes over it into electromagnet which draw in the other plate towards it. There is additionally a contact plate between them. The attractive field apply power to interface both these plates and grating plate transmit torque between them. Consequently this grasp is mix of both electromagnetic impact and mechanical grip. Presently we will examine development and working of this grasp.

Construction:

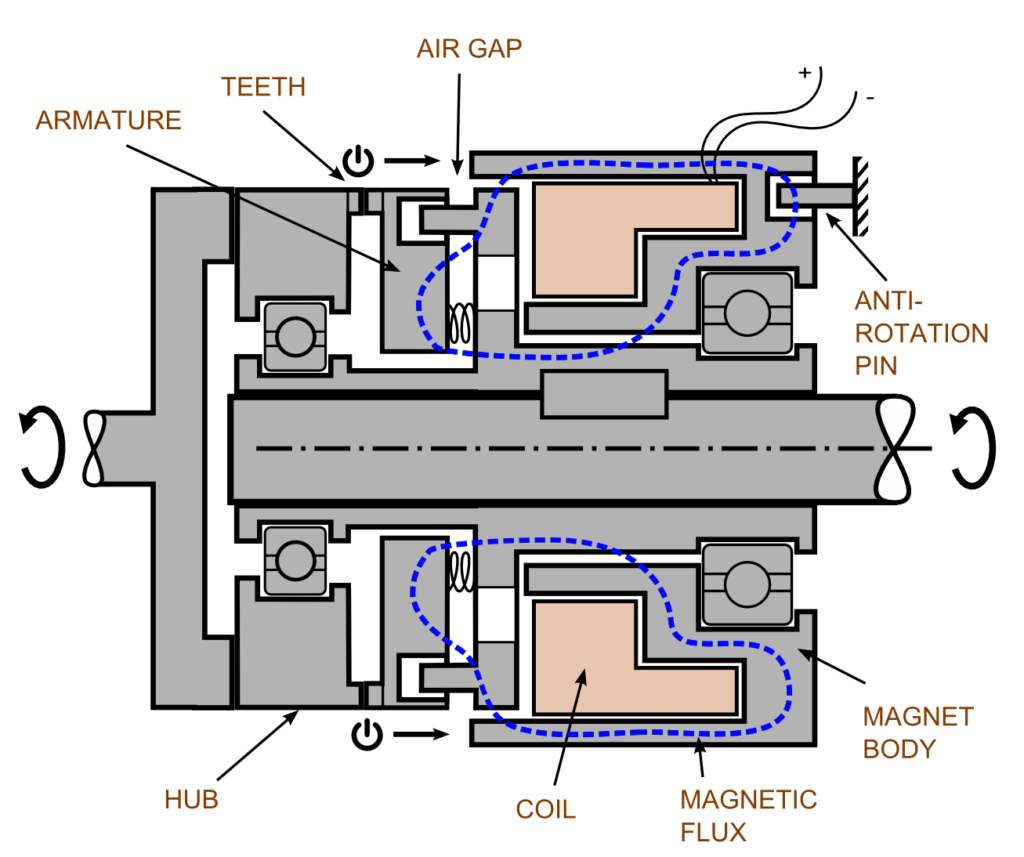

This clutch comprises following parts.

Rotor:

Rotor is a noteworthy piece of this grasp witch is associated specifically to the driving shaft or motor shaft. It ceaselessly pivot alongside the driving shaft.

Winding or Coil:

Winding loop is arranged behind the rotor and stays in stationary position amid grip working. It is appeared in figure. A high voltage DC supply is associated with this winding which exchange a high voltage current into this winding and convert it into electromagnet.

Armature:

Armature is arranged at front of the rotor. It is associated with the center point or weight plated with the assistance or bolt or shot joint.

Center point:

Center point or weight plate is darted with the apparatus shaft or driven shaft and pivots with it. It is arranged after the armature.

Friction Plate:

Rubbing plate is embedded among armature and rotor as indicated by the necessity.

Supply unit:

Supply unit comprise grasp switch, battery, wire and so on.

Working:

The electromagnetic grasp working can be condensed into following focuses.

In the underlying condition the grip is in separate position. There is an air hole among rotor and center point.

First the motor begins which makes turn the rotor associated with the motor shaft.

A DC battery supplies DC current into the grip winding.

This high voltage DC current proselytes this twisting into an electromagnet which draw in armature towards it.

This armature drive grinding plate towards the rotor and make turn the center point.

In this way the center pivot and the rotor transmit 100 percent torque amid draw in position.

At the point when the grasp switch/pedal is squeezed, the battery stops the supply in winding which evacuate the electromagnetic power, therefore the grip is in withdraw position.

Advantages:

No linkage is required to work the grip. So it very well may be introduced any remote area.

It very well may be utilized to accomplish programmed transmission.

Simple to work.

Less mileage at contact point.

Disadvantages:

This grip working temperature is constrained by the temperature rating of the protecting material.

High introductory Cost.